When the equipment cannot come to us, we come to your site !

Chimiderouil has a qualified and experienced intervention team with all the necessary means to intervene on site and clean pipes, tanks, boilers, heat exchangers, distillers, steam generators, etc., both in Belgium and internationally.

We take care of everything; products, personnel, effluent management… A treatment protocol and a prevention plan will be established before our intervention in order to ensure a safe service.

Our teams operate daily in sectors as varied as the pharmaceutical industry, the food industry, the petrochemical industry, the steel industry and many other sectors.

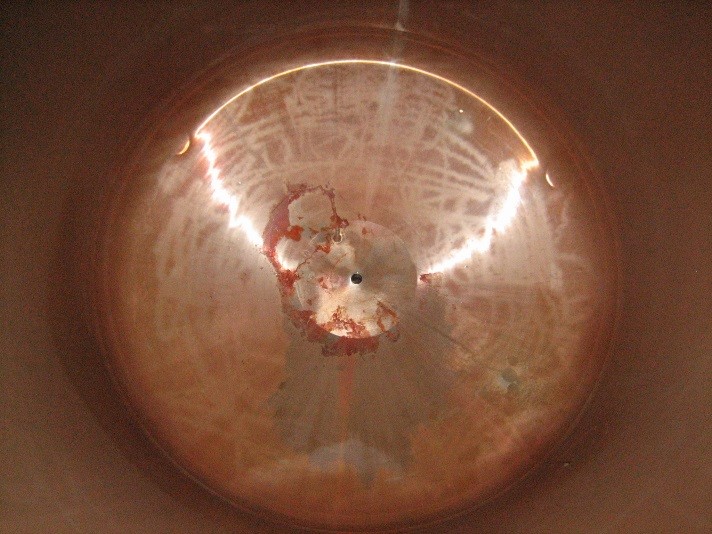

Descaling

Chimiderouil can help you solve your scaling problem, both from a preventive and curative point of view. Our teams take charge of managing the treatment of your installations, thus ensuring optimal performance of your installations!

Why descaling your exchangers and boilers There are two main reasons for descaling your exchanger.

On the one hand, the presence of scale will lead to excess energy consumption to ensure the proper functioning of the device, which will undeniably be felt on your energy bill: 1mm of scale deposited = 15% energy lost.

On the other hand, the scale deposit will adversely affect the proper functioning of the exchanger or boiler by increasing the risk of corrosion and reducing its lifespan.

Our long experience allows us to select the appropriate chemistry to solve your problems. Do not hesitate to contact our engineers to help you in your specific cases!

Before

After

Interested in our on-site services?

Before

After

Oxygen Degreasing

Oxygen service essentially requires the complete removal of contaminants such as

- greases

- hydrocarbon

- oils

- thread lubricants

- impurities due to work

- contaminated waters

- filings

- scale

- weld projections

- shavings

- paints

- varnish

- pencil marks

- rust

- oxides

- powdered metals

- packaging material

- labels

- wood fiber

or any other foreign material

Many of these materials, especially greases, more or less oxidized metal powder, hydrocarbons and oils can react violently in the presence of oxygen, causing fires and explosions. Others, such as metal shavings, can be propelled by a fluid circuit with sufficient speed to trigger an explosion on impact.

Chimiderouil offers the appropriate chemical treatments to prepare your installation, your pipes or exchangers for this type of specific application. We have the appropriate chemical formulations for each grade of steel and offer the appropriate means of control (Wood’s lamp, water film test, etc.). Our working methods correspond to the requirements of the Eiga IGC Doc 33/18 & Doc 13/20.

Derouging

Chimiderouil, through its experience in the field of stainless steel and the continuous development of new product formulations, can help you solve the rouging problems that you encounter in your installations.

Stainless steel installation rouging is the result of the development of iron oxide, hydroxide or carbonate coming from an external source or linked to the destruction of the passive layer of the stainless steel. The color variation is linked to the type of oxide formed and variation in the water associated with the corrosion process. Colors vary from orange to black.

A high-performance team will offer you a diagnosis and solutions adapted to your needs.

Pickling and Passivation

Pickling stainless steel consists of dissolving the mixed oxide layer formed during the welding process. This mixed oxide layer has a chromium content that is too low to allow the development of the passive layer specific to the “stainless” character of these steels.

Once this layer has been removed, the chromium present can oxidize on contact with air or water and form a continuous film: this is what we call the passivation phenomenon.

This passivation can either be formed “naturally” in contact with ambient air, or be accelerated by the chemical action of an oxidizing agent.

- Par circulation

- Par pulvérisation

- Par immersion

- By circulation

- By spraying

- By immersion